-

Personalised LED Wall Signs: Adding a Touch of Elegance to Your Office Environment

In today’s competitive business world, creating a professional and inviting office environment is crucial for success. Personalised LED wall signs offer a unique and elegant solution to enhance the ambiance of your workspace. In this blog post, we will explore the benefits and possibilities of incorporating personalised and best custom LED signs on walls of your office, from showcasing your brand identity to creating a memorable and visually appealing atmosphere.

Elevating Your Brand Identity

Your office space is a reflection of your brand, and personalised LED wall signs provide an excellent opportunity to showcase your unique identity. By customising the design, color, and typography of your LED wall sign, you can incorporate your company logo, slogan, or mission statement, creating a visually cohesive representation of your brand.

This reinforces brand recognition among employees and leaves a lasting impression on clients, partners, and visitors. The custom LED signs enable you to capture the essence of your brand and project it in a sophisticated and memorable way.

Creating an Inviting Atmosphere

The office environment plays a significant role in employee morale, productivity, and overall satisfaction. Personalised LED wall signs can transform the atmosphere, infusing it with a sense of warmth and professionalism. The soft, ambient lighting provided by LED signs creates a welcoming and soothing environment, making employees and visitors feel comfortable and inspired.

Additionally, the customisable features of LED signs allow you to choose colours and designs that align with your office decor and create a harmonious visual experience. Whether you opt for a sleek and modern design or a more traditional and refined look, personalised LED wall signs add a touch of elegance that elevates the overall atmosphere of your office.

Enhancing Wayfinding and Navigation

Large office spaces or corporate complexes can be challenging to navigate, especially for newcomers or visitors. Personalised LED wall signs can serve as effective wayfinding tools, guiding individuals through your office with ease. By strategically placing LED signs at key locations, such as entrances, conference rooms, or departmental areas, you can provide clear directions and eliminate confusion.

The use of custom fonts, symbols, or arrows on LED signs ensures that information is easily understood and accessible. Additionally, incorporating personalised LED wall signs with room numbers or employee names can further streamline navigation, enhancing efficiency and minimising disruptions.

Promoting a Memorable Experience

First impressions matter, and LED wall signs have the power to leave a lasting impact on clients, partners, and visitors. When they enter your office, they are greeted by a visually captivating and thoughtfully designed environment. The elegance and sophistication of custom LED signs create a memorable experience, making your office stand out from the crowd.

By incorporating elements of your brand identity and using high-quality materials, you communicate professionalism, attention to detail, and a commitment to excellence. This positive impression fosters trust, strengthens relationships, and sets the stage for successful interactions and collaborations.

Conclusion

Personalised LED wall signs offer a unique opportunity to add a touch of elegance to your office environment. The custom LED signs provide many benefits, from showcasing your brand identity to creating a welcoming atmosphere and enhancing navigation. By incorporating personalised LED wall signs into your office, you can transform your workspace into a visually stunning and memorable setting that reflects your brand and captivates everyone who enters.

Source By – https://bit.ly/3No7Cv9

-

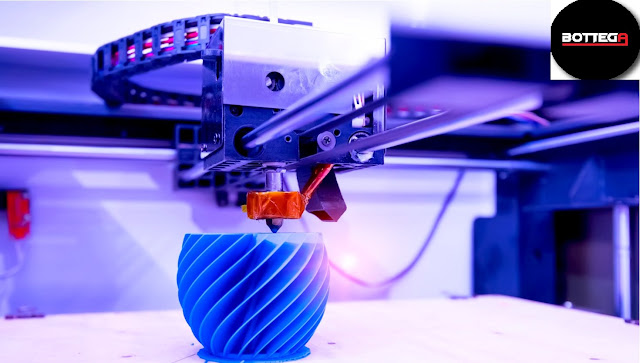

How 3d Printing Works: A Comprehensive Guide To Additive Manufacturing

3D printing is a rapidly growing industry, and it can be hard to keep up with all the new developments. That’s why we’ve written this guide! We’ll dig into some of the ins and outs of how 3D printers work, examine their advantages over traditional manufacturing methods, compare different types of 3D printers, and discuss where they’re used.

How does a 3D printer work?

To understand how 3D printing works, you need to know what a 3D printer is and how it works. In this section, we’ll explain the basics of additive manufacturing (the process of creating objects by adding material layer-by-layer). We’ll also cover some example 3D printers that illustrate different kinds of technologies and applications.

A 3D printer is an industrial machine used to create three-dimensional solid objects from digital models by depositing materials in successive layers until those objects are formed. The most common types of additive manufacturing technologies use plastic or metal as building materials; however there are also other options such as paper pulp or even food!

Fused Deposition Modeling (FDM) machines work by heating up plastic filament until it becomes liquid; this molten material then cools into solid form once extruded onto a platform inside the printer’s build chamber. As more layers are added on top of each other, they create objects with varying degrees of detail depending on how finely granulated each layer is printed out–from rough surface textures all way down through smooth lines & curves!

Advantages of 3D printing

You can use this technology to make one-off items, such as prototypes or specialised tools and fixtures, which are difficult or expensive to produce using traditional methods. This ability also makes 3D printing ideal for manufacturing parts that require complex geometries or intricate details.

The second major benefit of additive manufacturing is reduced waste during production. Even though the cost per unit produced may be higher than other processes like subtractive milling or casting, once you’ve made your design there will be no waste materials left over – saving both time and money on disposal costs!

Where does 3D printing take place?

In a factory, 3D printing takes place in a clean room. This is because the machine is large and creates some amount of dust as it runs. The printer itself is also very loud, so workers need to wear ear protection when they’re working with it.

The 3D printer can be used to make many different things: from medical devices like prosthetics or implants to toys or clothes (like this dress).

3D printing is a very useful technology that we can use to make many different things. It’s also fun and easy to use, so it’s no surprise that more and more people are getting interested in it.

Conclusion

3D printing is an exciting technology that has many benefits. It can be used to create objects that would otherwise be impossible to make with traditional manufacturing methods, such as injection molding or casting. 3D printers allow designers to iterate more quickly and efficiently than ever before, allowing them to produce prototypes of their designs at a lower cost than previous methods required.

Source By – https://bit.ly/3IEKWUM

-

Making Manufacturing Efficient: The Role Of Commercial 3D Printing Services

3D printing is a revolutionary technology that has the potential to transform many industries. From product design, to manufacturing and logistics, 3D printing can help companies be more efficient and profitable.

This article will focus on how best commercial 3d printing services can be used by manufacturers to streamline their production processes and make them more profitable.

Rapid Prototyping and Iteration

Rapid prototyping and iteration are a term that refers to the quick creation of prototypes. This process allows you to make changes in your design quickly, which can save time and money when developing new products.

Rapid prototyping services are used by many manufacturers because they allow companies to create 3D models of their products before they’re mass-produced.

The service typically involves building an object out of plastic or metal powder using computer-aided manufacturing (CAM) machines that use lasers or other technology to melt the material together layer by layer until it forms the desired shape.

Customisation and Personalisation

Customisation and personalisation are two of the most important factors when it comes to manufacturing. They allow you to create products that are unique, which can help your business stand out from competitors.

Customisation refers to the ability of a company or individual customer to change certain features of an existing product based on their needs or preferences.

Personalisation is similar but involves creating something new based on specific requirements or specifications provided by one person (or many).

.jpg)

On-Demand Manufacturing and Inventory Management

The benefits of on-demand manufacturing are numerous. It reduces inventory costs, waste, product development time and production time. On top of that, it can help companies reduce shipping costs by delivering products directly to customers’ locations.

The ability to print items when they’re needed means there’s no need for warehouses full of inventory sitting around waiting for orders or repairs.

This helps businesses save money while also reducing their environmental impact by cutting down on storage space requirements–not to mention the energy required during transportation!

Reduced Tooling Costs

The first and most obvious benefit of commercial 3D printing services is that they can reduce the costs associated with tooling. Tooling is a necessary part of the manufacturing process because it allows companies to mass produce parts quickly and efficiently, but it’s also expensive.

Commercial 3D printing offers an alternative way to prototype your designs while saving money on tooling development costs. If you need something made quickly or are unsure if a design will work as expected before committing significant resources into mass production, this option may be right for you!

In addition to saving money on tooling development costs, commercial 3D printing services can also be used when traditional methods aren’t feasible due to size limitations or other factors such as material availability (e., metal vs plastic).

Conclusion

In conclusion, it’s clear that commercial 3d printing services has a huge role to play in the future of manufacturing. It offers many benefits over traditional manufacturing methods and is already being used by many companies around the world.

We hope that this article has helped you understand some of the ways in which commercial 3D printing services can make your business more efficient!

Source By – https://bit.ly/3pUJcAc

-

What Are the Latest Innovations in 3D Printing Business?

The world of 3D printing is getting more advanced with each passing year. In fact, many people aren’t even aware of what’s possible with this technology and how it can be used in various industries and applications.

If you’re looking to learn more about the latest innovations in 3D printing business, then keep reading!

Advancements in Materials

In the last few years, 3d printing business has seen a number of innovations that have allowed for more advanced materials and more intricate designs. Now you can print with metals, ceramics and even carbon fibre.

This means that you’ll be able to create parts that are stronger than ever before. Some companies are also working on new ways to print complex geometries without sacrificing quality or strength–and they’re doing it by combining multiple materials in one print job!

Larger-Scale Printing

The most obvious use for this technology is to print larger-scale objects. If you have an object that’s too large to fit in your printer, or if it would take too long to print all at once, then this could be the solution for your problem.

The biggest advantage of this type of printing is that it allows you to print objects which would otherwise be impossible with traditional 3D printing methods (for example, creating a full-size car).

This has made it possible for companies like Local Motors and Stratasys – which produce large-scale 3D printers – to create their own businesses around producing products such as cars and planes through additive manufacturing techniques.

Speed and Efficiency

Speed and efficiency are two of the biggest benefits of 3D printing. The technology has allowed for a drastic reduction in time to market, which means you can get your product into the hands of customers faster than ever before.

In addition, it reduces costs by eliminating expensive tooling required for mass production and helps improve quality because there’s no need for manual assembly or complex post-processing steps like polishing or coating.

Smart 3D Printing

If you are a business owner, then you might be wondering what the latest innovations in 3D printing are. While there are many amazing things that can be created with 3D printing technology, one of the most exciting developments is smart 3D printing.

Smart 3D printers use artificial intelligence (AI) to predict and optimise their own performance based on information from previous prints.

They can also learn from other machines with similar capabilities that share data over a network, providing an even more efficient way for businesses to create products quickly and cheaply.

Conclusion

3D printing is a technology that’s still evolving, but it’s already making big changes in the world. By creating objects layer by layer from a digital file, 3D printers can make anything from jewellery to car parts to prototypes for new products.

And now there are even more ways of using this technology that could revolutionise how 3d printing business operate! To learn more information about 3D printing, contact professionals today.

Source By – https://bit.ly/44c68KO

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.